Environmental Waste Controls

Proven Protection: Environmental Controls That Work

At Emerald Energy from Waste, sustainability isn’t just a talking point; it’s a proven system. For over 30 years, we have provided the Greater Toronto Area with energy from waste through environmental waste controls, which strictly adhere to Ontario’s environmental regulations.

Skeptics and industry stakeholders can be confident we designed our emissions control systems with redundancy, reliability, and effectiveness in mind, supported by continuous monitoring, independent audits, and public reporting of data.

Air Pollution Control (APC):

Multi-Stage Defense & 24/7 Operation

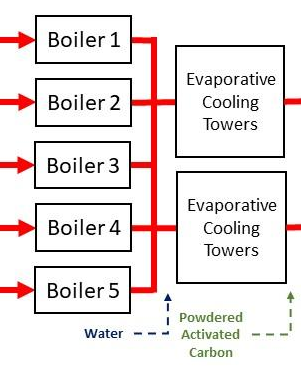

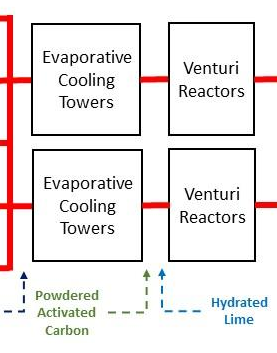

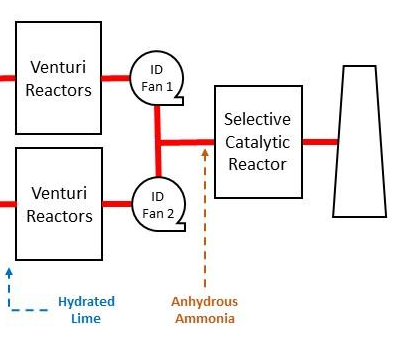

At the heart of our facility’s environmental performance is a robust, multi-stage Air Pollution Control (APC) system that operates 24/7 to ensure safe, clean emissions. Complete with evaporating cooling towers, venturi reactors, baghouse filters, induced draft fans, and a selective catalytic reactor, this system is designed to address the full spectrum of pollutants generated during energy recovery.

The APC process effectively removes acid gases, heavy metals, dioxins, furans, particulates, and nitrogen oxides. With two fully independent treatment trains, we uphold continuous environmental safeguards, even during routine maintenance, delivering reliability and compliance that surpass regulatory standards.

Specifically, all flue gases from our energy recovery process are treated to eliminate:

Acid gases (e.g., HCl, SO₂)

Mercury and heavy metals

Dioxins and furans

Particulate matter

Nitrogen oxides (NOx)

Environmental Control Technology

Breaking Down the APC System

Evaporative Cooling Towers

Rapidly Cools Flue Gas to Optimal Treatment Temperature

These towers cool flue gas to 180°C by utilizing a downward water spray. This quick cooling process prepares the gas for optimal contaminant capture and ensures suitable reaction conditions for acid gas treatment.

Venturi Reactors

Injects Hydrated Lime and Powdered Activated Carbon (PAC) to Neutralize Acids and Adsorb Toxic Compounds

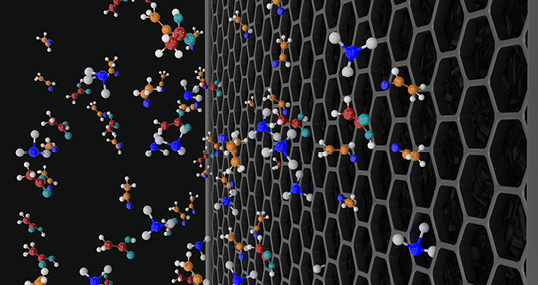

Turbulent flow promotes effective mixing of flue gas, hydrated lime, and powdered activated carbon (PAC). These reagents chemically neutralize acid gases and physically capture:

-

- Mercury

- Heavy metals

- Dioxins and furans

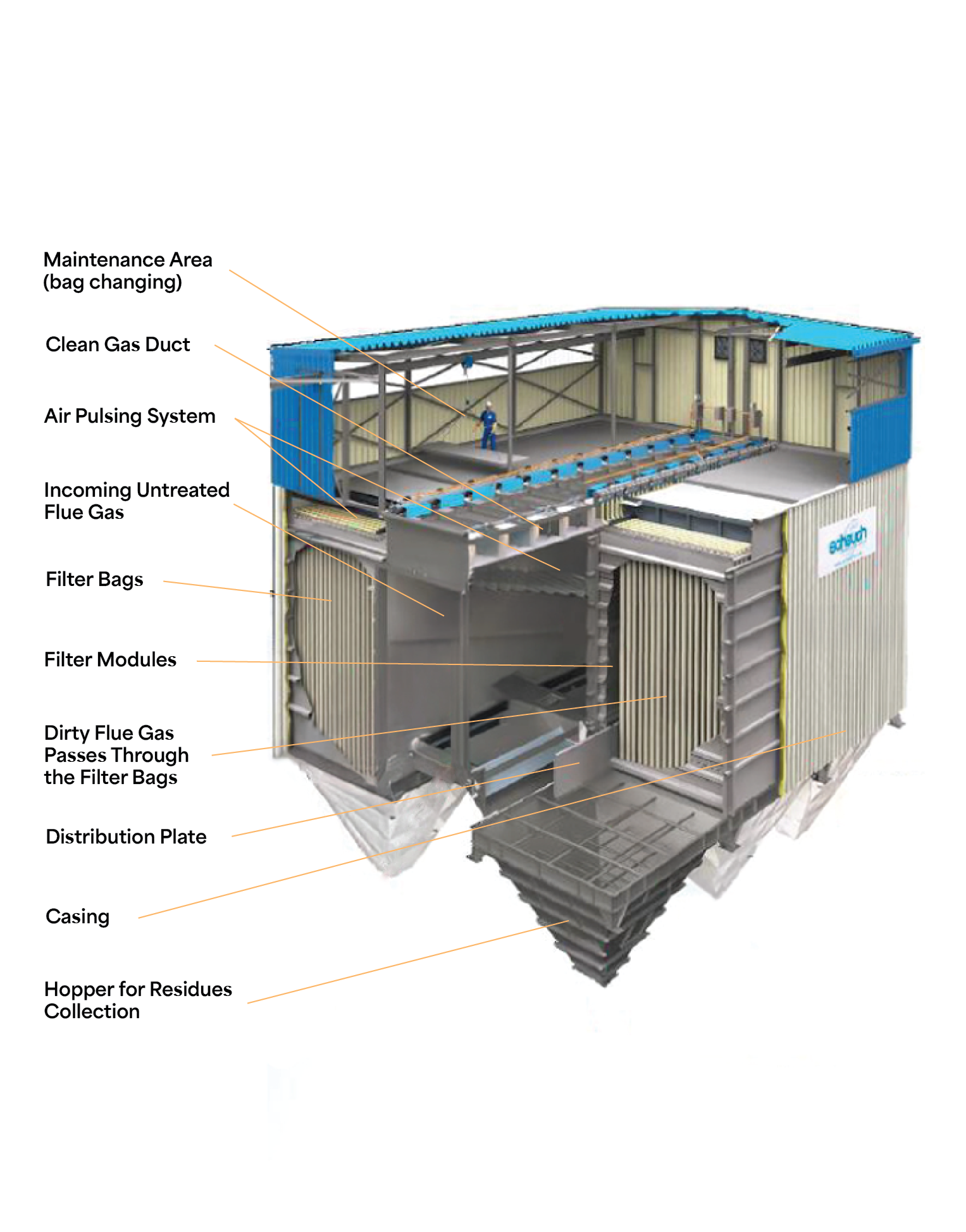

Baghouse Filtration

Removes Particulate Matter with Over 3,900 m² of Filtration Surface

The baghouse captures remaining particulates, from ash to reagent dust, using over 3,900 m² of specialised filter material. Clean gas is then drawn through the system by our Induced Draft Fans.

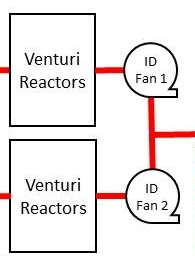

Induced Draft Fans

Pull Flue Gas Through the Entire Treatment System and Maintain Plant-Wide Airflow

Powered by 400 hp electric motors, our dual ID fans ensure the plant’s airflow is maintained. If one is offline for maintenance, the other continues operating without interruption. The fans direct flue gas into the SCR system and out through the main stack.

Final Treatment: Selective Catalytic Reduction (SCR)

Flue Gas is Converted into Nitrogen and Water Through Ammonia Injection and Titanium Oxide Catalysts

After treatment, the flue gas enters our Selective Catalytic Reduction (SCR) system, where it is converted into nitrogen and water through ammonia injection and titanium oxide catalysts. This system doesn’t just meet environmental standards; it’s designed to exceed them, acting as our ultimate barrier against NOx emissions. Here’s how it works:

- Flue gas reheated to 230°C using a natural gas burner

- Anhydrous ammonia injected into the stream

- Gas flows through dual Titanium Oxide catalyst beds

- NOx is converted into harmless nitrogen and water

As an additional benefit, any residual dioxins or furans that remain are further oxidized in the SCR. The outcome? An exhaust stream that consistently meets and often exceeds Ontario’s stringent environmental limits.

Environmental Waste Controls

Continuous Emissions Monitoring (CEM): Verified in Real-Time

Our compliance isn’t based on assumptions; it is measured and verified every minute of every day.

Our CEM system includes:

- CO and O₂ analyzers to track combustion efficiency

- HCl monitors to measure acid gases at multiple points

- Opacity sensors for visible emissions control

- NOx monitors before and after treatment

We also conduct third-party stack testing annually, monitoring for:

- Heavy metals

- Volatile and semi-volatile organics

- PCBs, dioxins, and furans

All results are submitted to the Ontario government quarterly and annually, ensuring full transparency.

Sustainability you can measure

For ICI stakeholders, regulators, and environmentally conscious customers, Emerald Energy from Waste provides a proven, accountable model of how energy-from-waste can be operated responsibly and sustainably.

Emerald Energy from Waste’s environmental control system is designed for:

High-performance contaminant removal

Zero downtime emissions protection

Verified compliance and public transparency

Proven Climate Benefits

By diverting residual municipal waste from landfills and recovering energy, Emerald Energy from Waste reduces greenhouse gas emissions by approximately 908,000 tonnes of CO₂e annually, which is equivalent to removing nearly 200,000 cars from Ontario roads.

This supports Ontario’s transition to a circular, low-carbon economy while reducing dependence on cross-border transport and distant landfill infrastructure.

Built to Keep Waste Out of Landfills

Emerald Energy from Waste delivers a proven solution: we convert non-recyclable waste into energy, reducing landfill use and supporting your environmental targets.