Our Technology

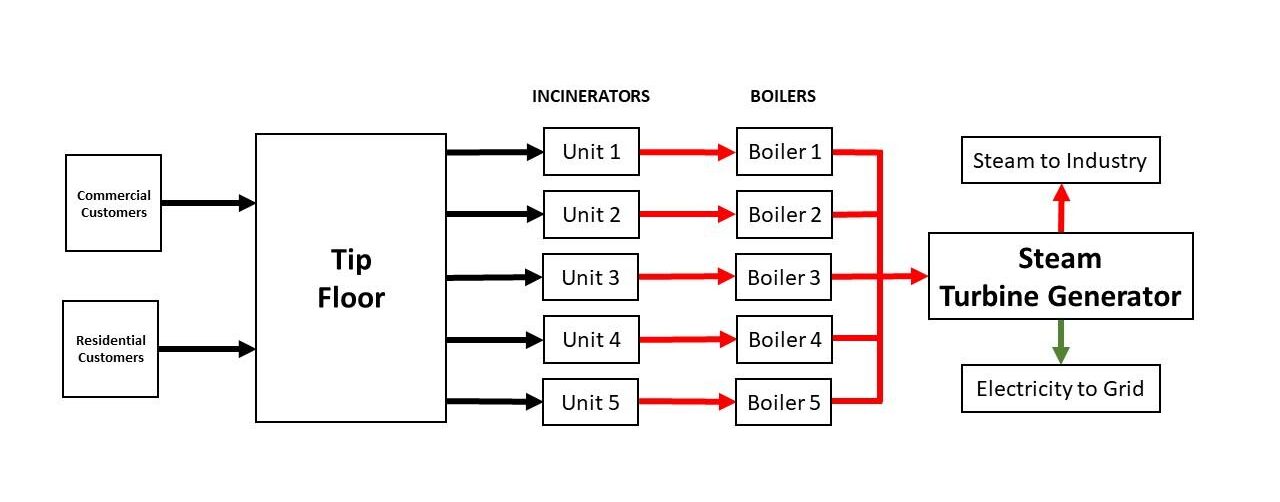

Waste Delivery

Waste arriving at the site is deposited on the tip floor where it is screened by our operators for ‘unacceptable’ materials (non-compliant or over-sized materials). The screened waste is stored on the tip floor before being fed into the incinerators by a front-end loader.

The tip floor can store approximately 2,250 tonnes of waste, about 4-5 days of feedstock for the incinerators.

Incinerators

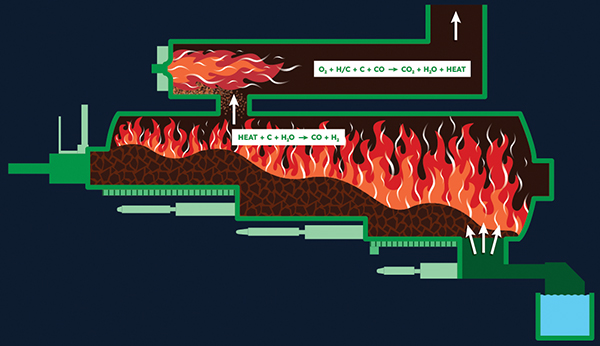

The waste is put into one of 5 Consumat gasifiers. Each gasifier consists of a Lower and an Upper Chamber. Waste fed into the Lower Chamber is heated in a low-oxygen environment for approximately 6 hours at 750-850° C. The heated waste breaks down into a ‘syn-gas’ which is rich in combustible compounds.

The syn-gas is drawn into the Upper Chamber where it is combusted into an oxygen rich environment at a temperature of at least 1,000°C.

Approved Capacity:

90 to 110 tonnes/day

Design Heating Value:

5 500 Btu/lb (12 764 kJ/kg)

Operation Temperatures:

750 – 850°C (lower chamber)

1 000 – 1 100°C (Upper chamber)

Combustion Gas Residence:

1 s (minimum)

Boilers

The combusted gas (flue gas) from the Upper Chamber is passed into a water tube boiler for heat recovery. The hot flue gas enters the boiler at a temperature of 1,000°C. As the gas passes over the water tubes, the water in the tubes absorbs the heat and is converted to steam. The temperature of the flue gas leaving the boilers drops to 230°C.

Approved Capacity:

12,250 kg/hr (27,000 lb/hr)

Operating Pressure:

600 psig (4,238 kPa)

Steam Temperatures:

343°C (650° F)

Steam Turbine

Steam from the boilers is directed to a steam turbine generator. The electricity from the steam turbine generator powers the facility with the remainder being exported to the grid.

Model:

Howden Turbine Twin CA510

Rated Output:

9.0 MW

Operating Pressure:

600 psig (4,238 kPa)

Output Voltage:

4,160 VAC, three phases @ 60 Hz