Energy Recovery

Electricity Generation

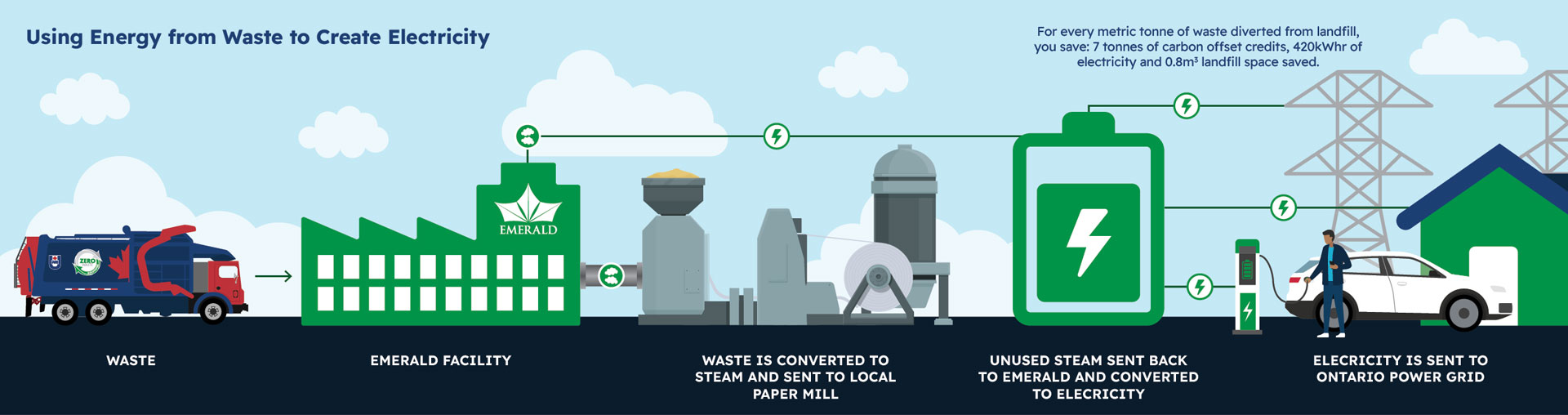

Upon its commencement in 1992, the Emerald facility exclusively generated electricity as its primary energy product. The initial turbine employed was a single-stage turbine dedicated to producing electricity for on-site use. Any excess electricity generated was put toward the Ontario grid.

Fast forward to 2021, significant upgrades were implemented at Emerald. Including the replacement of the original turbine with a more advanced two-stage turbine. This strategic upgrade was aimed at optimizing energy recovery efficiency. Additionally, the new turbine not only generates electricity but also produces saturated steam. Presently, our facility continues its commitment to supplying electricity for internal use while contributing surplus electricity to the Ontario grid. This development proves our dedication to advancing technology and continuing energy sustainability practices.

Steam Export

In 2008, a steam pipeline was constructed with the purpose of delivering saturated steam to a local recycled paper manufacturer. This initiative, driven by Emerald’s commitment to sustainable practices, resulted in the elimination of the necessity for a dedicated coal or gas-fired boiler at the paper plant, thanks to the export of steam generated through our energy-from-waste operation.

The steam pipeline operates as a closed-loop system, exemplifying a sustainable and efficient energy exchange process. Emerald supplies steam to a local paper mill, where the energy in the steam is utilized. Further, the spent steam, in the form of condensate, is then returned to Emerald for reuse in the process.

The above-ground segment of the steam pipeline at the Emerald site travels via a pipe bridge to our property boundary, where it descends 8 meters below grade to pass beneath Bramalea Road. Continuing below grade on the east side of Bramalea Road en route to the paper plant, the pipeline system incorporates 7 underground vaults. These vaults serve the dual purpose of maintenance activities and aiding thermal expansion of both the steam and condensate pipelines.

In conclusion, this collaborative project yields mutual benefits for both Emerald and the paper mill. Emerald notes improvements in energy recovery efficiency, aligning with sustainable energy practices. Simultaneously, the paper mill shows a significant reduction in its reliance on natural gas. Thus, showcasing the project’s positive environmental impact and contribution to resource conservation.

Future Energy Products

Emerald continually looks for opportunities to produce energy products that provide value to our community. Currently, we are looking at other energy products including:

Green Hydrogen

Emerald is actively exploring a pilot project aimed at the local commercialization of hydrogen production. Leveraging surplus power generated at our facility, Emerald envisions the potential to yield up to 500 kg of electrolytic hydrogen daily.

The electrolytically produced hydrogen holds the prospect of contributing significantly to our decarbonization efforts by displacing a portion of the natural gas used in operations. Moreover, the oxygen made during the electrolysis process offers a valuable avenue to mitigate the volume of flue gas produced in our energy recovery operations. This reduction in flue gas volume carries the dual benefit of lowering our harmful electricity demand and curbing the emission of nitrogen oxides.

Alternatively, the hydrogen output could play a pivotal role in addressing contaminant and carbon emissions within the transportation sector. Specifically, hydrogen emerges as a viable fuel for direct application in established fuel cell vehicles, such as buses and trains. With a delivery range of up to 100 km from Brampton, the hydrogen could be supplied to customers at a cost that competes favorably with diesel prices.

The versatility of the hydrogen extends to its potential use as a combustion supplement for diesel-powered trucks, buses, or trains. The co-combustion of hydrogen with diesel not only enhances fuel efficiency but also removes soot and emissions. This application of hydrogen as a diesel fuel supplement serves as a transitional technology. Thus, paving the way for the community to realize the environmental advantages of hydrogen while waiting for more advanced commercial fuel cell technologies.

District Heating

Emerald is exploring implementing district energy solutions in the Bramalea Rd/407 vicinity. Specifically, the focus is on introducing district heating. Wherein low-pressure steam sourced from the Emerald facility would be used to supply heat to nearby industries, warehouses, or large residential buildings. By harnessing steam generated through our energy recovery processes, customers in the district heating system could entirely forego the need for natural gas in heating their facilities.

Emerald is eager to engage in discussions regarding district heat opportunities. Specifically with commercial property owners or developers situated in the Bramalea Rd/407 area. The potential collaboration aims to not only enhance energy efficiency but also contribute to sustainable practices within the local community.